Still Have Questions?

Reaching us is easy!

Tel: 802-472-8700

Email:

[email protected]

YOU HAVE QUESTIONS, WE HAVE ANSWERS!

What is PolyWhey?

PolyWhey is the trade name for the patented processed used by Vermont Natural Coatings to use whey protein, a byproduct of cheese making, as the transformative ingredient in its wood finishes.

PolyWhey has greater durability, with a cured hardness that is twice that of the average water-based finish. It also has 25% less VOC content than the standard that most water-based finishes try to meet. PolyWhey accomplishes this by using whey, a natural, renewable resource, as its bonding agent.

What is PolyWhey?

PolyWhey is the trade name for the patented processed used by Vermont Natural Coatings to use whey protein, a byproduct of cheese making, as the transformative ingredient in its wood finishes.

PolyWhey has greater durability, with a cured hardness that is twice that of the average water-based finish. It also has 25% less VOC content than the standard that most water-based finishes try to meet. PolyWhey accomplishes this by using whey, a natural, renewable resource, as its bonding agent.

Is it durable?

Absolutely. Independent tests confirm that Vermont Natural Coatings PolyWhey finishes are among the most durable on the market. They have stood the test of time on residential and commercial floors and in furniture manufacturing.

What makes PolyWhey a Green product?

Our formulations use whey protein as the bonding agent. Whey is a renewable resource and a natural by-product of the dairy industry. This use of a natural product in our professional finishes translates to low VOCs, and better indoor air quality.

What does VOC stand for?

VOCs are Volatile Organic Compounds. Many VOCs are relatively harmless, and are produced naturally. Vegetation is a major source of isoprene, a VOC that is released naturally during the life and eventual decay of tree species like eucalyptus and oak. Many plants use VOCs to communicate with other plants in their ecosystems and even use them to send SOS messages when a threat is present. However, not all VOCs are created equal. Many VOCs can cause great harm to not only our environment, but also to our health. Some, such as formaldehyde and benzene, are even known carcinogens (chemicals known to cause cancer in humans).

How do VOCs work?

VOCs are emitted into the air as a gas from different liquids or solids during curing or aging. This is called off-gassing, and this process does not necessarily stop when the products you have used in your house have dried / do not smell any more. Many products contain harmful VOCs that will off-gas into your home for years, invisibly and odorlessly contaminating your indoor air quality. Dangerous VOCs are commonly found in a variety of different products that you likely already have in your household.

Products that Often Contain Harmful VOCs:

Products that Often Contain Harmful VOCs:

- Paint and paint thinner

- Wood stain and finishes

- Aerosol sprays

- Household cleaners

- Room deodorizers

- New cabinets, furniture, rugs

- New wood floors

- Candles

- Nail polish / nail polish remover

- Pesticides

- Gasoline & other petroleum products

- Personal care products

Health Effects of VOCs:

With all the products available on the market that contain VOCs, it can be challenging to avoid them. However, it is important to be aware of the adverse effects of VOCs and the potential long term health effects they can cause.

VOCs can cause:

- Eye, nose, throat irritation

- Headaches

- Dizziness

- Nausea and vomiting

- Nosebleeds

- Liver, kidney, and nervous system damage

How VOCs Affect Our Environment:

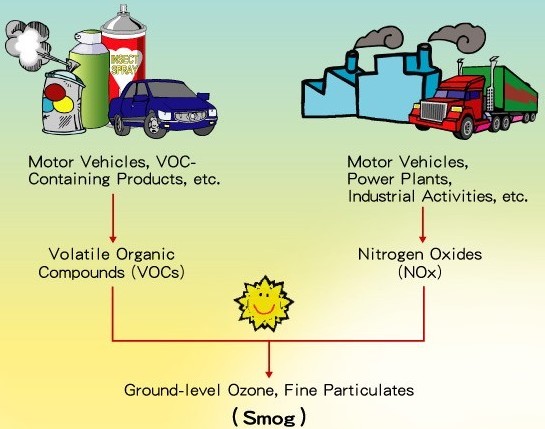

Volatile Organic Compounds play a big role in creating the ground-level ozone. The ground-level ozone layer itself can cause harm to our health. VOCs also “play a significant role in the formation of ozone and fine particulates in the atmosphere. Under sunlight, VOCs react with nitrogen oxides emitted mainly from vehicles, power plants and industrial activities to form ozone, which in turn helps the formation of fine particulates” (source).

Volatile Organic Compounds play a big role in creating the ground-level ozone. The ground-level ozone layer itself can cause harm to our health. VOCs also “play a significant role in the formation of ozone and fine particulates in the atmosphere. Under sunlight, VOCs react with nitrogen oxides emitted mainly from vehicles, power plants and industrial activities to form ozone, which in turn helps the formation of fine particulates” (source).

How Vermont Natural Coatings is Helping to Combat Dangerous VOCs:

We recognize that harmful VOCs are a big problem that our planet is facing. All of our products are heavily monitored for safety and are considered either VOC free or Ultra-Low VOC. The VOC level for Vermont Natural Coatings finishes range from ≤180g/L (grams per liter) in our Floor Finish to zero VOC in our Penetrating Water Proofer Infused with Juniper.

The toughest indoor air quality standard for wood finish in the United States is California’s 275g/L, we far surpass this standard with our Ultra-Low VOC products.

For more information about VOCs and to find more products that are safer for you and your family, visit our partners at Rise, a building supply store focused on educating consumers and providing resources for a healthier and more environmentally friendly home.

Sources:

Environmental Protection Agency. (n.d.). EPA. Retrieved August 3, 2022, from https://www.epa.gov/indoor-air-quality-iaq/what-are-volatile-organic-compounds-vocs

Volatile Organic Compounds (vocs). Minnesota Pollution Control Agency. (2021, May 19). Retrieved August 3, 2022, from https://www.pca.state.mn.us/air/volatile-organic-compounds-vocs

(1)Volatile organic compounds and smog. Environmental Protection Department. (n.d.). Retrieved August 3, 2022, from https://www.epd.gov.hk/epd/english/environmentinhk/air/prob_solutions/vocs_smog.html

What is the VOC level in Vermont Natural Coatings?

The VOC level for Vermont Natural Coatings finishes range from ≤180g/L (grams per liter) in our floor finish to zero VOC in our Penetrating Water Proofer Infused with Juniper. The toughest indoor air quality standard for wood finish in the United States is California’s 275g/L.

What makes Vermont Natural Coatings safe?

Our products not only contain ultra-low VOC levels, but they also are free from carcinogens, mutagens and reprotoxins that can still be found in many products that claim to have low or no VOCs.

How soon can I walk on my newly finished PolyWhey floor?

Once the finish is dry, it can be walked on with care. Keep in mind, the less action the surface sees before it has come to a full cure, the better. Do not put anything fibrous on the floor until it has come to a full cure – rugs, newspaper, cardboard, etc. The important distinction here is the difference between ‘dry’ and ‘fully cured’. While your PolyWhey surface will feel dry to the touch within a few hours of application, full cure time is seven days.

Do VNC finishes contain Flame Retardants?

PolyWhey finishes do not contain any flame retardants. Chemical flame retardants added to paints and coatings are known to be carcinogenic, harmful to human health, and release even more toxins when they do burn. Our finishes do not contain any of these harmful chemicals, nor do they increase the flame spread of an existing fire.

What is a Class A Flame Spread Rating?

Flame spread ratings categorize a surface material’s capacity to catch, burn and spread flames in an existing fire. Materials are ranked on a scale of increasing flammability from Class A – C. PolyWhey finishes have a Class A Flame Spread rating, the lowest and safest possible in the industry.

What is Zero Flash Point?

Flash point refers to the temperature at which the vapors of a volatile substance will ignite. PolyWhey finishes have zero flash point – this means that the vapors of our finishes do not spontaneously combust.

Application

Is it easy to use?

Very easy to use. Our floor and furniture finishes self-level and have great flow, ensuring a uniform finish. We recommend a light sand with fine grit after the first coat. You can apply with a brush, foam brush, or paint pad. For detailed application instructions- (take from current website)

Is it easy to use?

Very easy to use. Our floor and furniture finishes self-level and have great flow, ensuring a uniform finish. We recommend a light sand with fine grit after the first coat. You can apply with a brush, foam brush, or paint pad. For detailed application instructions- see product pages.

Does it yellow when exposed to UV light?

Our interior finishes remain clear when exposed to interior UV light. PolyWhey Exterior has UV inhibitors to protect your decks, fences and siding from the sun’s rays.

How do I prepare a surface for a VNC finish?

If applying to previously finished wood, sand in order to remove old finish before applying new finish. If sanding entire surface is not desired, be sure to sand areas of distress that can cause flaking, in order to blend edges. Apply the product directly to the surface or the sealer coatings.

Is it possible to have a different level of gloss?

PolyWhey Furniture finish is available in gloss, semi-gloss and satin. PolyWhey Floor finish is available in matte, semi-gloss and satin. Large volume customers should contact us to request a custom finish.